- Out-of-Stock

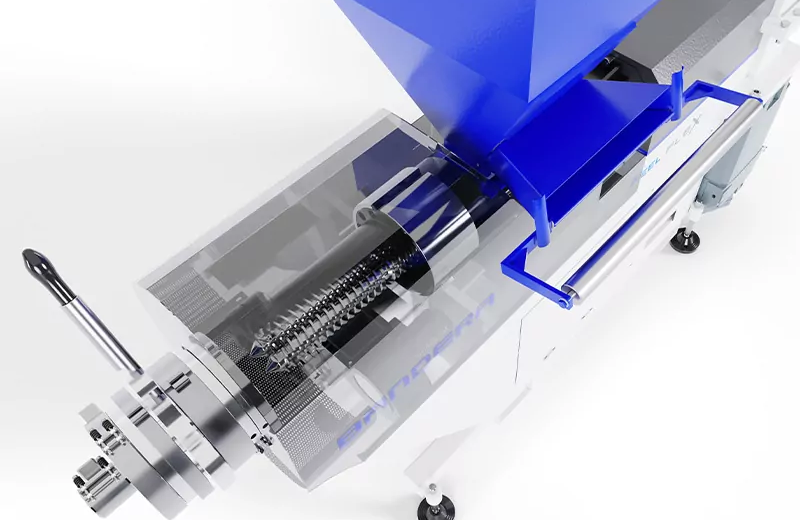

Reel FLEX® has been specially designed for complex productions where the quantity of lines implies a high accumulation of production waste. It is a very flexible solution that adapts to any form of plastic waste solving the disposal problems.

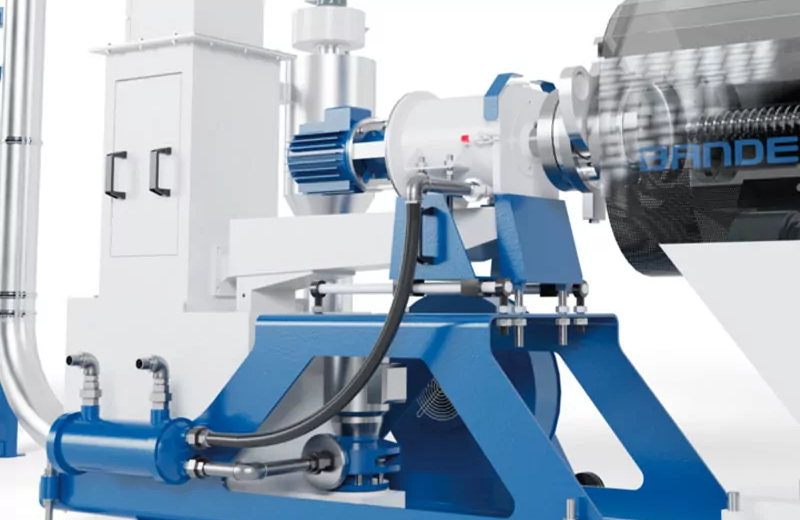

Advanced degassing system for simultaneous humidity extraction and VOC (optional).

Optimal gelling and careful mixing of the material thanks to the innovative screw-cylinder profile under patent.

Perfect mixing of multilayer materials thanks to double screw.

Configurable feeding for all types of waste: reels, bulk, trimmings, folders, fluff, etc.

Water-jet cutting and pelletiser with dedicated die for superior granule quality even at higher productivity.

Manual filtration device to remove dust or other contaminants that may have deposited on the material during storage (optional).

Reel FLEX® i72

Maximum flow rate 150 kg/h – 330.7 lb/h