- Out-of-Stock

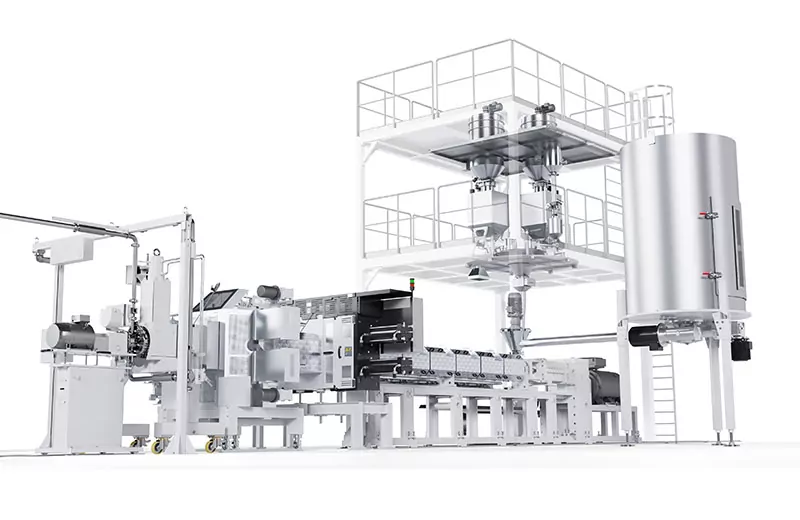

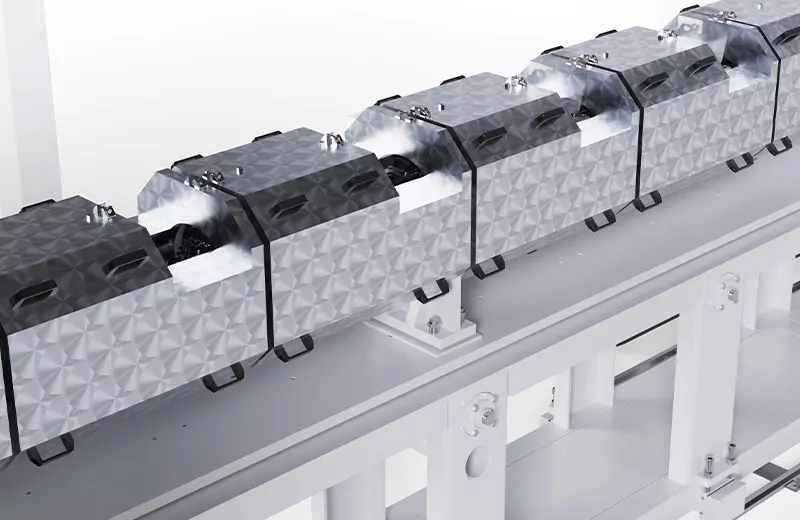

Solution that allows processing the blends of heterogeneous materials while maintaining all the original characteristics unaltered. Ideal equipment for the production of premium materials.

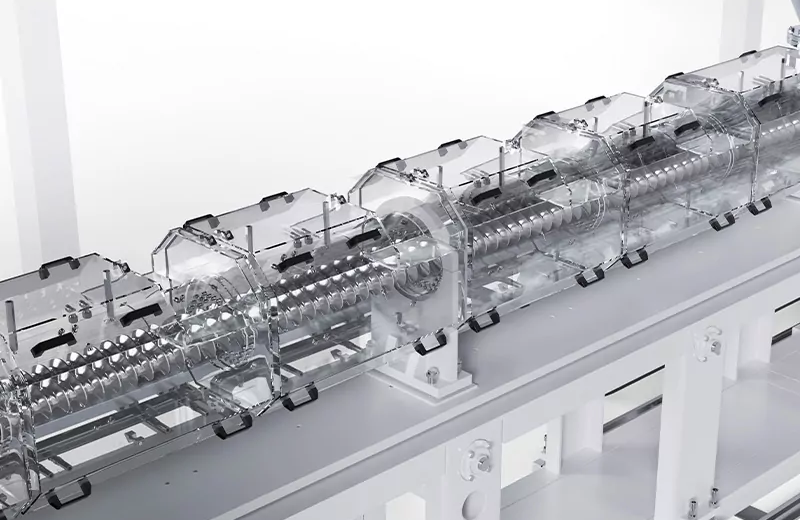

The gear pump, in combination with a partial filling of the extrusion chamber, ensures minimal fluctuation with a steady process.

The Bandera process enables to apply a double filtration system which allows the extraction of value even from the most critical materials.

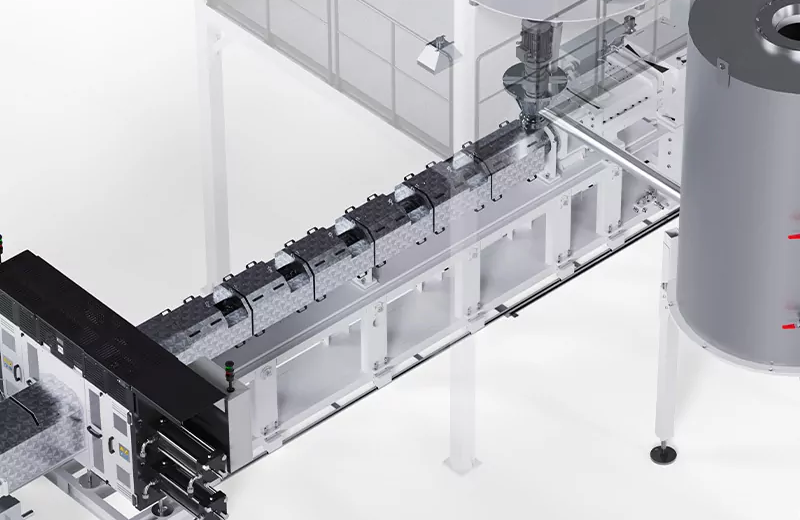

Feeding of any type of material to be recycled: flexible fluff with low bulk densities; rigid flakes or granules. Suitable feeding and dosing systems are supplied for each type of material, volumetric with forced feeding or gravimetric.

TWIN PCR105

Capacity 650 – 1.000 kg/h | 1 433,0-2 204,6 lb/h

TWIN PCR135

Capacity 1.000 – 2.000 kg/h | 2425,0-4409,0 lb/h

TWIN PCR170

Capacity 2.100 – 3.000 kg/h | 4629,7-6613,9 lb/h