- Out-of-Stock

The AC-C series includes water/air cooling coils for the cooling of blown film extrusion lines (packaging) with production included between 120 and 1250 kg/h.

The range is available in two versions:

• MONO for OBC cooling.

• TWIN, with stacked coils, for OBC and IBC cooling.

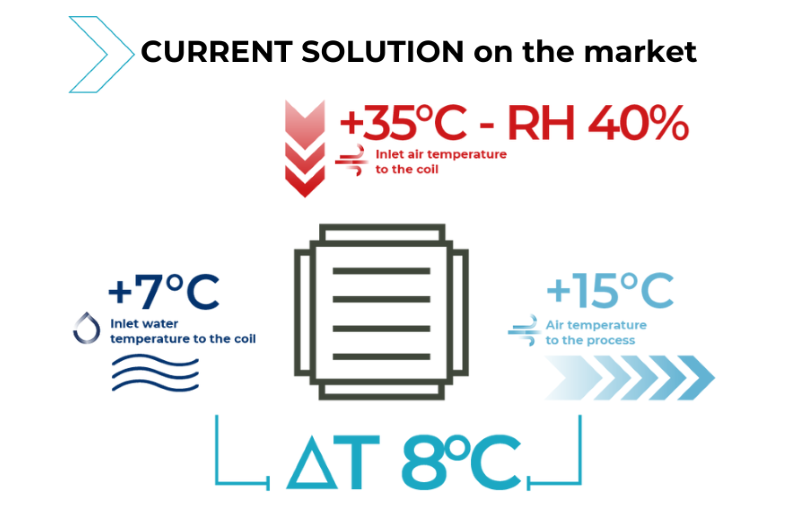

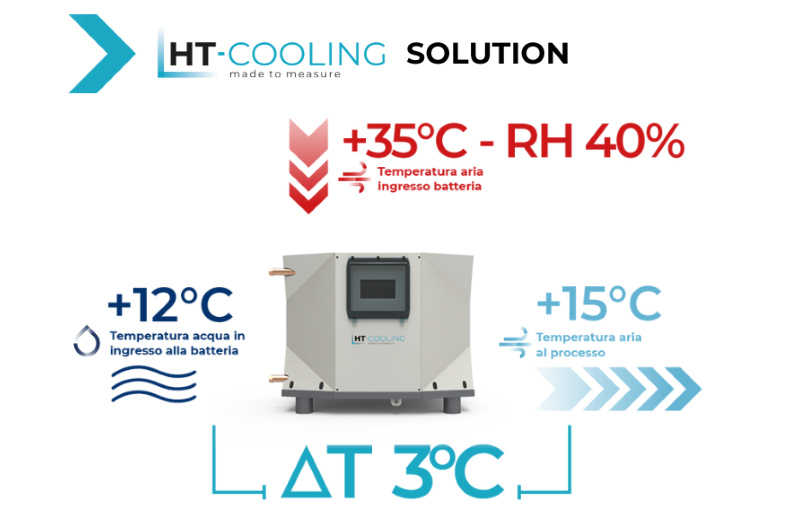

Our coils can be supplied to replace existing ones by operating with inlet water 5°C higher than current solutions on the market, thus requiring a reduced cooling input.

External structure is made of galvanized sheet metal and painted with fine polyester powders (RAL9002 and RAL7037) with effective resistance to corrosive agents.

Internal structure is made of galvanized sheet metal.

All components are sealed and riveted to ensure excellent sealing.

The air connections are of the OK type (JACOB type: optional), sealed and welded to the internal frame.

A pressure gauge is installed externally to survey and monitor pressure of the water entering the machine.

Each coil is supplied complete with adjustable anti-vibration feet for flat positioning even on surfaces with a slight difference in level.

The high-efficiency exchanger has a large exchange surface and is made with aluminum fins and copper tubes. The larger surface area allows the speed of the air to be limited without the use of a droplet separator: the oversizing of the exchanger also allows the electrical consumption of the process fan to be reduced.

The exchanger is designed to work with cold water at temperatures just 3°C lower than the required outlet air temperature: this allows for significant energy savings on chilled water consumption compared to more conventional solutions.

Air temperature reading and regulation system can be easily set by the operator on an electronic control protected by an IP65 transparent door.

The control allows the adjustment of the electronic 3-way valve to keep the outlet air temperature constant.

• Pressure gauge to survey water pressure

• Easy-removable filter for maintenance operations

• Electronic, modulating 3-way valve

• NTC probe to survey the inlet water temperature

• Initial and clamp for smooth pipe connection

• Support brackets for coils in TWIN configuration

• JACOB type air connections

• OK/JACOB air connection adapters

• Dirty air filter alarm

• Y-shaped filter on water inlet

• Board for RS485 communication